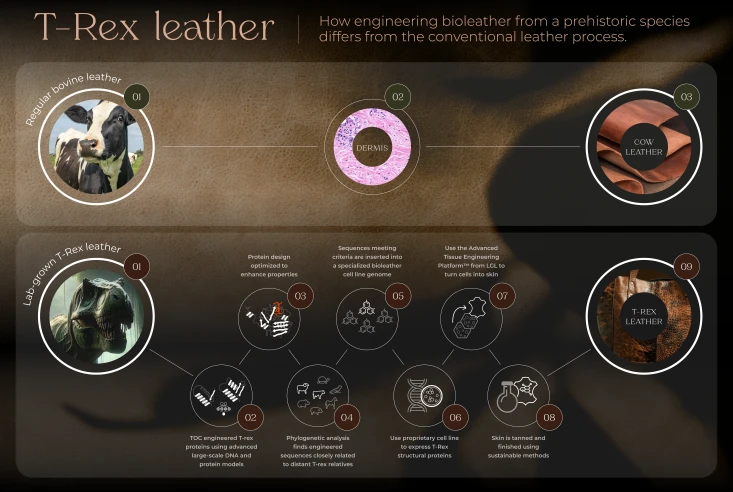

Lab-grown leather is an animal-free material engineered to replicate the look, feel, and durability of animal leather without traditional livestock farming. Unlike synthetic “vegan leather” (usually plastic-based, like PU or PVC), lab-grown leather uses biological processes—cells, microbes, or plant-based mycelium—to create a natural material. LGL is a biotech company specialising in producing real leather via tissue engineering rather than from slaughtered animals. Their mission: provide sustainable, cruelty-free, traceable leather alternatives that match the structure, feel, look, strength of traditional leather.

They use an Advanced Tissue Engineering Platform (ATEP™) to grow leather, starting from skin (dermal) cells. The cells produce collagen etc.

A key feature: their leather is scaffold-free. That is, they avoid using external scaffolds or synthetic frameworks that some other bioleathers use to hold structure. The idea is that cells self‐organise into natural tissue structure.

They grow only the dermis layer (skin structure), removing/omitting the parts like fat, epidermis, hair etc, so that what remains is more directly usable for tanning into leather.

They use an Advanced Tissue Engineering Platform (ATEP™) to grow leather, starting from skin (dermal) cells. The cells produce collagen etc.

A key feature: their leather is scaffold-free. That is, they avoid using external scaffolds or synthetic frameworks that some other bioleathers use to hold structure. The idea is that cells self‐organise into natural tissue structure.

They grow only the dermis layer (skin structure), removing/omitting the parts like fat, epidermis, hair etc, so that what remains is more directly usable for tanning into leather.

Advantages & Strategic Position

Ethically better: avoids animal slaughter; cruelty-free. Environmentally better in many respects: less land, water use; reduced deforestation; lower emissions vs conventional leather when considering livestock raising, tanning etc. Also removing synthetic scaffolds and plastics reduces plastic pollution. Traceability: Because it’s lab grown, production can (in principle) be more tightly controlled/monitored. Potential to scale into markets beyond fashion: automotive interiors, luxury accessories, aerospace, etc.

LGL is positioning itself as a partner to luxury brands who want sustainable, premium materials.

They also seem focused on white-label / B2B: supplying material to brands, not (primarily) direct to consumer. Sample shipments to brands are underway.

Innovation seems important: patented platform; product differentiation (thickness, strength, novel aesthetics etc) is their competitive lever.

About Lab-Grown Leather

Lab-grown Leather Ltd is a new business, based in Newcastle Upon Tyne UK, being developed by BSF Enterprise Plc to scale up the technical development and operational sales of animal skin products. BSF Enterprise Plc, founded in 2018 and listed on the London Stock Exchange in 2019, is focused on developing sustainable biotechnological solutions through industrial tissue engineering.

Lab-grown Leather Ltd focuses on producing a cultivated dermal skin, that replicates natural skin and once tanned has an identical composition to traditional leather, guaranteeing the same performance. its lead product is called “Elemental LeatherTM“

Lab-grown Leather Ltd utilizes a unique “scaffold-free” tissue engineering technology. This means that unlike some other lab-grown leather approaches and many plant-based alternatives, Elemental LeatherTM is made without additives or scaffolding, allowing the cells (including engineered cells) to create their own natural structure. This is considered a significant advantage, leading to a more authentic and durable end product that is more compatible with traditional leather processing techniques, including tanning. While other bio-based alternatives exist, such as plant-based fungi-based and inorganic glass fibre-based leathers, Elemental LeatherTM is claimed to be “true leather” as it is made entirely from animal cells and the proteins they produce creating the same structure as traditional leather. This results in a material that is structurally and genetically identical to traditional leather, offering the same durability, feel, and versatility.

The project’s developers say the lab-grown material will be fully biodegradable and structurally identical to traditional leather. It will also be “innovative and ethically sound,” Che Connon, professor of tissue engineering at Newcastle University, said in a statement.

Connon also works for biotechnology company Lab-Grown Leather, which is developing the project with Dutch creative agency VML and genomic engineering firm The Organoid Company.

“We’re unlocking the potential to engineer leather from prehistoric species, starting with the formidable T-Rex,” added Connon, who is one of the project’s leaders.

Connon and his colleagues may be eyeing the fashion industry — market data provider Fortune Business Insights says the global $500 billion leather goods market will be worth $855 billion by 2032 — and sectors beyond, such as the automotive industry.

Professor Che Connon CEO Lab- Grown Leather Ltd explained that the collagen fragments extracted is available from blood vessels or micro-vessels in bone.

But Connon rebuked the notion that it’s not possible, telling The Post that “some people have got the wrong end of the stick saying, well, you can’t do it. That’s not true.” “Some of that seems to be around, there is no T-Rex skin, but leather isn’t skin. It’s a component of skin,” he explained. “So that’s a bit of confusion there. The technologies there are incredible, but they are very much there. And I think the challenge is, there’s a lot to bring people up to speed with.” As he explained, the collagen fragments extracted are available from blood vessels or micro-vessels in bone, and the blood vessels have the same biological makeup as skin. “It’s the structural part of the skin, which forms leather.” “People aren’t aware of all the different technologies or aware that they exist, so putting them together is quite a bit of a mental leap for people,” Connon said. “But rest assured, these are all things that have been proven.”

Eventually, this could open the door to possibilities beyond the fashion industry, such as the automotive sector.

The researchers also stressed the environmental and ethical consequences of the lab-grown leather as well. Since traditional leather production is a component of extensive deforestation and the tanning process often uses harmful chemicals, this new approach can not only reduce negative environmental impacts but also put an end to animal cruelty concerns.

“Dinosaurs evolved to survive in extreme environments conditions our planet is once again beginning to face due to accelerated climate change,” the news release also explained.

Lab-Grown Leather, based in Newcastle, teamed up with The Organoid Company to grow extinct hides using dinosaur DNA.

A full-length collagen sequence will be generated for the dinosaur, which will be used to grow new skin.

Until recently, it was thought dinosaur DNA would be impossible to find because the fragile strands do not survive over tens of millions of years.

However, in the past decade, paleobiologists found collagen preserved in dinosaur fossils, including an 80 million-year-old Tyrannosaurus Rex.

‘Innovative and ethically sound’

In 2023, Lab-Grown Leather became the first biotech company to successfully culture fully natural animal skin, and now believes it can use its technology to recreate T-Rex hide. The team believes the leather will be tough and durable, and hopes to have its first product available by the end of the year.

Prof Che Connon, of Lab-Grown Leather, said: “We’re unlocking the potential to engineer leather from prehistoric species, starting with the formidable T-Rex. This venture showcases the power of cell-based technology to create materials that are both innovative and ethically sound.” Lab-Grown Leather was the first to create animal skin without using a scaffold to coax the tissue into the correct alignment. Instead, scientists managed to recreate the biochemical and biophysical cues that occur in the body to make the cells spontaneously arrange themselves in the correct pattern. It means that there is no need to use animal-derived serums to help kick off the growth process or blends and fillers that other synthetic meat and skin companies need, which prevents products from feeling natural. Without the need of artificial scaffolds or fillers, the leather that is produced is 100 per cent animal tissue, without any extra animal products.

To create T-Rex leather, the team plans to piggyback on recent research that extracted a fragment of the collagen protein from a T-Rex fossil. The Organoid Company will use the fragment to recreate what the full-length T-Rex collagen would have looked like, then convert it into a DNA sequence and engineer it into the Lab-Grown Leather cell line genome. If all goes well, it should produce a dense network of T-Rex collagen, similar to a dermis. The dermis is the structural part of skin, which is all that remains after tanning, so the process should re-create T-Rex leather.

Thomas Mitchell, the chief executive of The Organoid Company, added: “This project is a remarkable example of how we can harness cutting-edge genome and protein engineering to create entirely new materials. “By reconstructing and optimising ancient protein sequences, we can design T-Rex leather, a biomaterial inspired by prehistoric biology, and clone it into a custom-engineered cell line.”

‘Ground-breaking collaboration’

Fossils suggest that T-Rex skin was scaly, rather than having feathers like many dinosaurs, so the result is likely to be close to that of modern reptiles. The experts are working alongside VML, a Netherlands-based innovation company, which helped to create the first meatball made from the DNA of a woolly mammoth in 2023. The team took the DNA sequence for mammoth myoglobin, a key muscle protein in giving meat its flavour, and filled in the gaps using elephant DNA. “With T-Rex leather, we’re harnessing the biology of the past to create the luxury materials of the future,” said Bas Korsten, the global chief creative officer at VML.

At Lab-Grown Leather Ltd, the mission is to transform the global leather industry with sustainable, cruelty-free, and traceable alternatives. Using our proprietary ATEP™ platform, we create 100% lab-grown leather identical to the real thing—without animals, additives, or waste. We exist to meet rising environmental and ethical demands while delivering unrivalled quality. to lead the next generation of luxury and performance materials. Our vision is to scale Elemental Leather™ across industries from fashion to aerospace—proving that sustainability, performance, and beauty can coexist. By pioneering traceable, high-quality leather alternatives, they strive to become the preferred partner for forward-thinking brands worldwide.

For More Information and enquires contact: https://lab-grown-leather.com/

Lab-Grown Leather Ltd,

2 Portman Street London W1H 6DU United Kingdom